Light on Weight. Heavy on Performance.

Experience an enhanced, innovative design with the addition of new, optional features!

The enhanced LDM Series now offers two optional upgrades for improved performance and safety. The addition of a fixed rear bar chain increases efficiency and reduces discharge, creating a safer work environment. Additionally, a custom-designed pin mount is now an option, perfectly tailored to your carrier, ensuring seamless integration with your equipment.

The LDM Series excavator mulcher from Promac Equipment is expertly crafted and rigorously tested in North America. It has been approved for use on the rugged west coast by those who know it best. With its proven durability and top-notch performance, it's the perfect choice for handling the most challenging conditions.

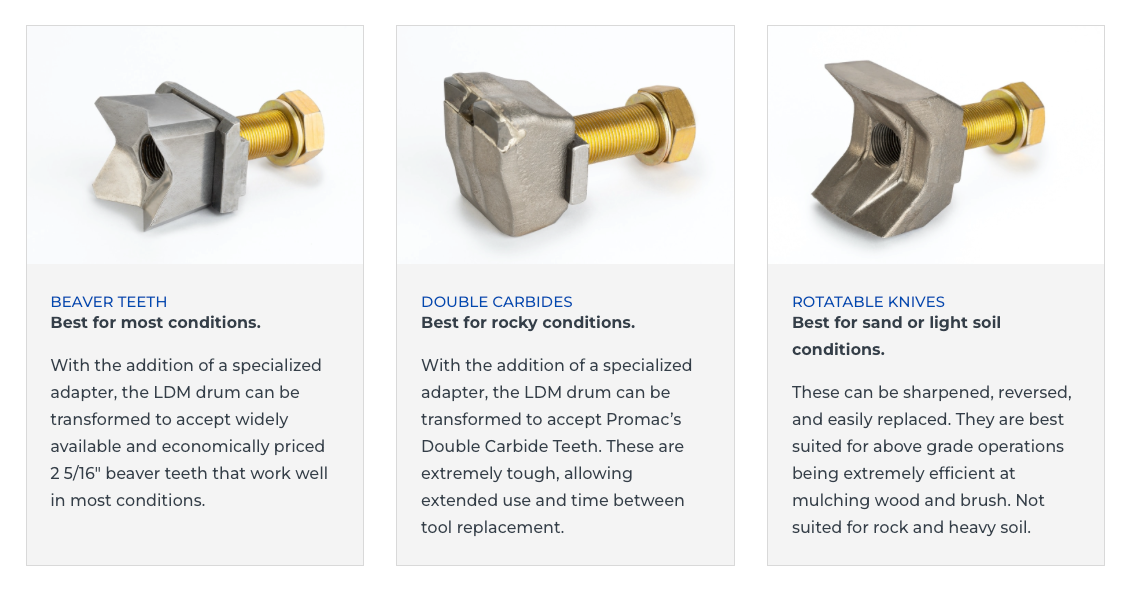

As a professional in the industry, you can easily adjust the hydraulic flow of the LDM Series to as low as 15 GPM @ 5000 PSI to suit various applications. Its capabilities in handling brush and trees efficiently are enhanced by its 30" and 50" cut widths, and the option to choose from three different cutter teeth based on your specific working conditions.

The mulcher operates through a hydraulic bent-axis piston motor with variable tension and Promac's Automated Torque Control (ATC) for maximum efficiency and performance. High-strength steel and easily replaceable wear-resistant parts are utilized by Promac for long-lasting and seamless operation.

Upgrade to the upgraded LDM Series excavator mulcher and enjoy better performance, increased safety, and improved durability for your forestry operations. Rely on Promac for high-quality equipment that meets your needs and surpasses your expectations.